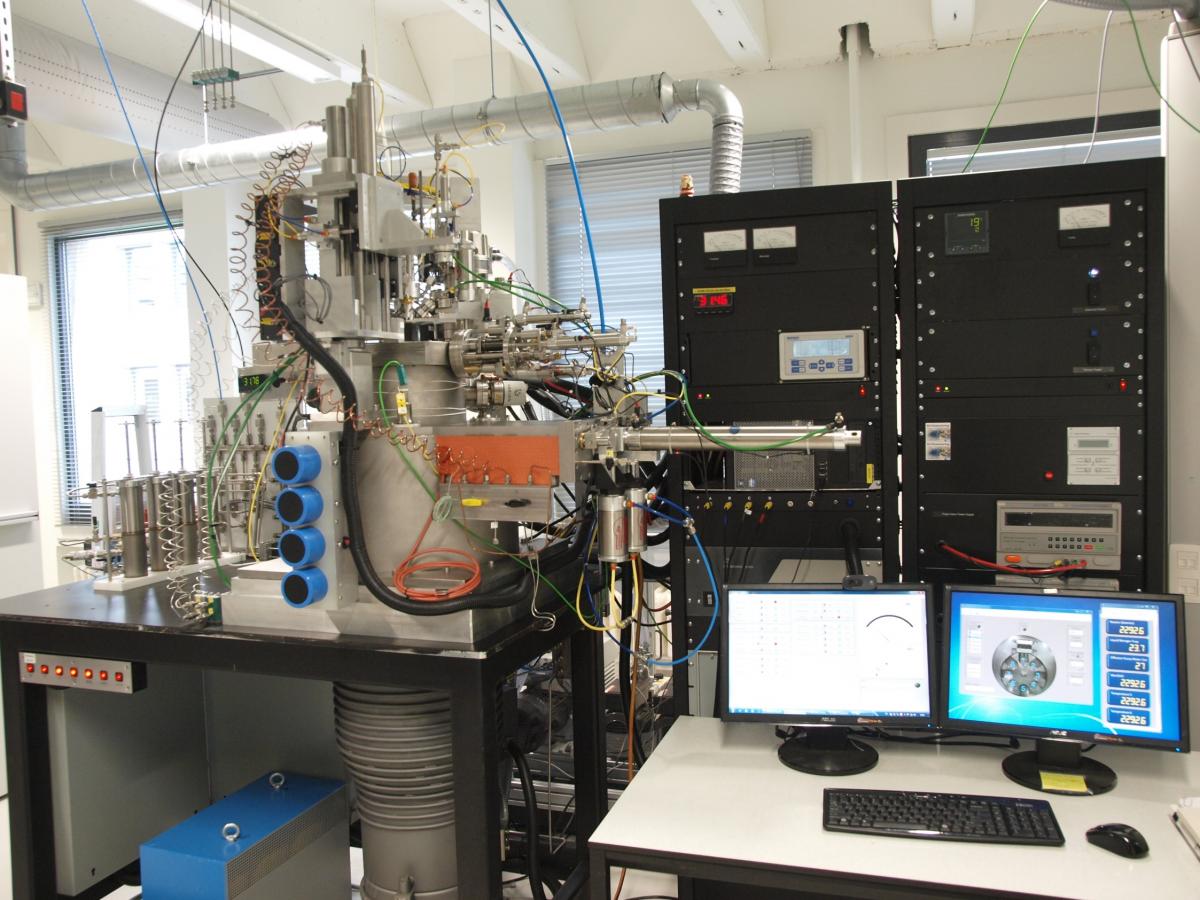

TAP Reactor System for Materials Kinetic Characterization

The Temporal Analysis of Products (TAP) Reactor System is used to characterize the reaction kinetics of chemical conversion over materials or heterogeneous catalysts. Characterizing the relationship between surface composition and kinetic properties enables the rational design of materials based on microkinetic detail from simple reaction steps. The advantage of Temporal Analysis of Products (TAP) comes from the small pulse size (approximately 1014-1016), which is several orders of magnitude smaller than the number of active sites in a typical sample. As a result, from pulse to pulse, the kinetic state of the material can be probed without inducing a significant change. Over a long series of pulses a material can be incrementally manipulated, for example from oxidized to reduced. Observing the evolution of kinetic properties from TAP data can shows how the processes such as bulk oxide transport, surface diffusion, number of active site, site blockage, reaction products and effect of the surface intermediates and products impact the reaction mechanism. This information can be used to better understand deactivation mechanisms or to distinguish why materials of similar composition and preparation perform differently at process conditions.